Strategies to maximize your screen’s productivity

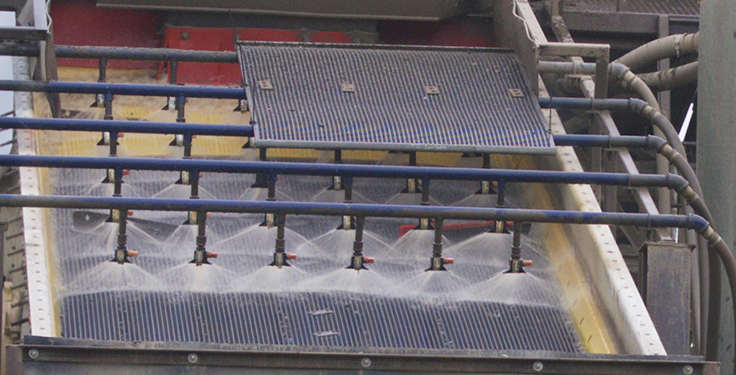

Integrating eccentric screening tech, state-of-the-art screen media and diagnostic tools can prevent blinding, pegging, carryover or contamination, improving screening performance, productivity and profits. Photo: Haver & Boecker Niagara

Every ton of material must go over at least one vibrating screen. Ensuring equipment performs efficiently is critical to an operation’s success.

The good news is there are technologies available that can enhance screening productivity. Integrating eccentric screening technology, state-of-the-art screen media and diagnostic tools can prevent blinding, pegging, carryover or contamination, improving screening performance, productivity and profits.

Heighten screening action

Vibrating screens that are engineered with a double eccentric shaft assembly create a constant stroke to maintain g-force during material surging.

The double eccentric shaft design forces the screen body to follow the movement of the shaft. While the shaft travels up, the counterbalance weights move in the opposite direction and create a force equal to what is generated by the body. As a result, the forces cancel each other out and maintain a consistent positive stroke that handles material volume spikes without losing momentum.

Reduce damaging vibrations

Additionally, a vibrating screen’s operation can have a large impact on a machine’s surroundings.

The metal springs on a traditional concentric vibrating screen, for example, can be noisy to operate. This metal-to-metal, up-and-down or side-to-side movement can cause excessive noise and vibration.

To resolve this problem, double eccentric technology makes use of shear rubber mounts that are strategically designed to minimize lateral movement. The rubber mounts reduce noise while maintaining smoother operation – even in extreme circumstances such as overloading, surging and starting or stopping under load.

The use of eccentric technology virtually eliminates vibration in the structure – or chassis when used with portable equipment – protecting the integrity of the machine. This means producers can potentially use multiple eccentric vibrating screens in one structure and boost productivity.

Attempting to operate multiple concentric machines in a structure, however, can create vibrations damaging enough to not only cause a negative effect on the quality of production, but open the door to safety risks and possible downtime.

Improve stratification

By analyzing applicational requirements, producers can strategically select a blend of screen media that maximizes their vibrating screen’s performance in all phases of screening – from layered to basic to sharp. Photo: Haver & Boecker Niagara

Combining the use of advanced eccentric screening technology with the best screen media for the application is a recipe for success.

Specifically, polyurethane screen media can be beneficial to operations seeking to prevent blinding and pegging while improving material stratification and increasing wear life.

Polyurethane media offers the combination of open area and wear life for wet and dry applications. Polyurethane screen media that is poured open cast can offer up to double the wear life versus injection-molded products.

Open-cast polyurethane permanently hardens when cured to maintain its chemical properties and improve wear life. Polyurethane media also features tapered openings to reduce the risk of blinding and pegging.

The solution to improving material stratification lies in finding the ideal mix of screen media types to ensure all phases of screening work correctly. Companies that offer a variety of screen media types can help evaluate how material moves through the three phases of screening – from layered to basic to sharp – to give recommendations on the best screen media for an application. Producers can customize the screen deck by choosing screen media that maximizes productivity for each phase by blending the best combination of open area and wear life.

Prevent equipment damage

Vibration analysis software monitors a vibrating screen’s performance in real time by detecting problems before they lead to diminished performance, decreased efficiency and increased operating costs. Photo: Haver & Boecker Niagara

A vibrating screen needs regular checkups to run optimally.

Vibration analysis and diagnostic systems designed specifically for vibrating screens by OEMs are reliable tools for maintaining continued efficiency and longevity of screening machines. To ensure the best productivity, operations can partner with OEMs that specialize not only in manufacturing equipment, but offer diagnostic tools, product-specific knowledge and years of engineering experience.

Utilizing vibration analysis software, for example, allows aggregate operations to monitor a vibrating screen’s performance in real time by detecting problems before they lead to diminished performance, decreased efficiency and increased operating costs. The most robust systems incorporate wireless sensors that magnetically fasten to key areas of a vibrating screen and measure orbit, acceleration, deviations and other important datapoints that indicate the condition of the machine. The sensors send real-time information wirelessly to be analyzed.