Lighting mobile equipment for safer surface mining operations

In the NIOSH study, illuminance on the platform of equipment was typically the best compared to levels measured on the ground below the first step and the first step, especially in the presence of task lighting. Photo: NIOSH

Workers in the surface mining industry encounter slip, trip and fall hazards on a routine basis.

Inadequate illumination is associated with non-fatal incidents and injuries. Illness data from the Mine Safety & Health Administration (MSHA) shows that slips, trips and falls are the second leading cause of non-fatal incidents.

Mobile equipment operators are among the most common occupations associated with nonfatal incidents reported to MSHA, and mounting and dismounting equipment (ingress/egress) typically contributes to the largest proportion of nonfatal incidents. Moreover, results from a recent study indicate that mobile equipment operators identified proper illumination as a superior feature of safe ingress/egress systems.

The physics of lighting & seeing

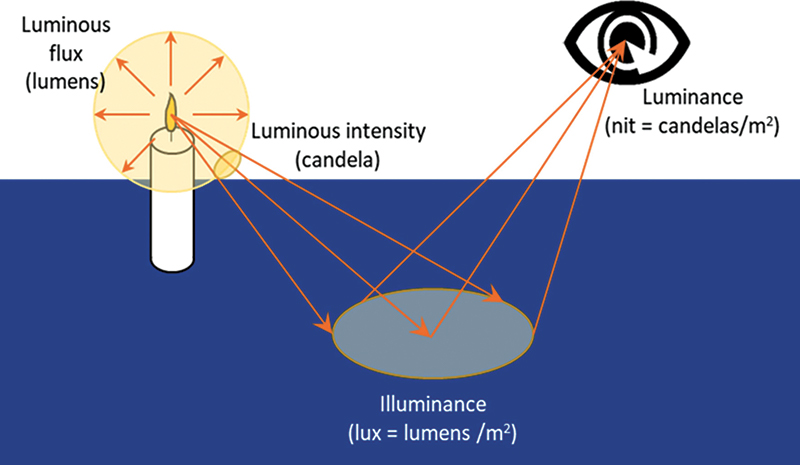

Lighting and, ultimately, seeing occurs because of a light source, or luminaire, emitting rays of light called luminous flux in all directions (measured in lumens). Photo: NIOSH

Lighting and, ultimately, seeing occurs because of a light source, or luminaire, emitting rays of light called luminous flux in all directions (measured in lumens).

The luminous intensity of the light is measured in candelas at a certain point around the luminaire. The intensity of luminous flux that strikes a surface is referred to as illuminance and is measured in lux, which is equivalent to lumens per square meters. Incident light from the surface is directed to the eye, and the reflected light measured at the eye – or what the eye sees – is the luminance, which is measured in nits or candelas per square meters.

Given the complexity of this process, to measure light effectively in the mining environment, a specialized instrument to measure illuminance must be used.

The field study

NIOSH researchers measured illuminance levels with an incident light meter, which was placed horizontally with the sensor facing upward. Photo: NIOSH

Researchers from the National Institute for Occupational Safety & Health (NIOSH) conducted a field study that evaluated illuminance levels on and about mobile surface mining equipment and their ingress/egress systems.

Lighting was assessed on 38 mobile mining machines: 19 haul trucks, 12 front-end wheel loaders, three bulldozers, three excavators and one motor grader. Researchers took all measurements during pre-dawn hours to represent start-of-shift activities in the fall-winter-spring months.

Measurements were taken at the ground below the first step, at the first step and at the platform leading to the cab. The heights of these measurement locations varied according to equipment type. Researchers measured illuminance levels with an incident light meter. To ensure effective measurement, the meter was placed horizontally with the sensor facing upward.

The findings

The Illuminating Engineering Society’s (IES) recommended illuminances for generic types of activities, outdoor facilities and common applications. Click to enlarge | Source: IES

Task lighting was accomplished with either a headlamp, headlights from a non-mining vehicle, or a combination of both.

Illuminance levels on the first step were poor with no task lighting. In addition, illuminance on the ground was low even with task lighting (possibly due to shadows). Illuminance on the platform was typically the best compared to levels measured on the ground below the first step and the first step, especially in the presence of task lighting.

These trends are similar across all equipment evaluated (i.e., haul trucks and wheel loaders).

Importantly, illuminance levels were inadequate when compared to standards recommended by the Illuminating Engineering Society (IES). The IES recommendation is 100 to 200 lux in working areas where visual tasks are only occasionally performed. This was the case for visual inspections prior to boarding, and particularly for the first step on ladders and stairways and the ground below the first step – even when auxiliary task lighting was present.

Ways to improve lighting

To meet IES-recommended levels, mine operators can improve lighting on mobile equipment ingress/egress systems by exploring options such as:

• Using portable light plants with a tower-mounted light source in parking areas

• Directing available machine-mounted light sources toward the ingress/egress system.

• Using handheld or preferably hard hat-mounted lamps

• Using reflective or retroreflective materials (i.e., added to ladder steps or the front edges of stairs) to enhance the contrast between the target object (first step) and its background (ground below first step) for visual inspection tasks. Note that such materials should be non-slip and not interfere with the surface drainage of water or debris.

• Installing appropriate building-mounted or stationary pole-mounted area luminaires.

Alan G. Mayton currently works at the Pittsburgh Mining Research Division (PMRD) of the National Institute for Occupational Safety & Health (NIOSH), Centers for Disease Control and Prevention (CDC). Mahiyar F. Nasarwanji contributed to this article as an employee of PMRD/NIOSH/CDC.