L&H Industrial introduces tramp-release system

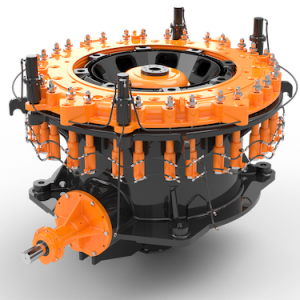

L&H Industrial’s new tramp-release system replaces conventional mechanical springs. Photo: L&H Industrial

L&H Industrial debuted a tramp-release system designed to ensure safety, dependability and ease of installation.

According to L&H, tramp in a crusher can lead to expensive equipment damage, hydraulic and lubrication leaks, and bushing and bearing damage. Tramp can also cause significant periods of downtime. As a high-value asset in the processing operation, the company says a tramp event or a related issue directly impacts safety, productivity, maintenance and the overall operation.

L&H says its system removes stored energy by replacing conventional mechanical springs. It also releases pressure on the cylinders and allows the adjustment to pick up, repressurizing cylinders to return to the optimal crushing position. The system delivers simplistic design, PLC logic and a large clearing stroke. L&H says the system requires minimal maintenance and can be installed in less than 24 hours.

The tramp-release system can be retrofitted onto legacy crushing equipment for an upgrade in safety and production, the company adds. L&H says the system can increase production levels by allowing the crusher to run at maximum feeds without fear of a tramp event.