Equipment options to consider in crushing, breaking

Excellence line hammers from Rammer are designed for harsh and demanding conditions, according to Allied Construction Products. They offer features such as an integrated smart RD3 remote monitoring system to track operating hours, GPS location and service intervals. Additionally, the company’s Performance line breakers are designed with operator comfort in mind, bringing powerful breaking solutions while minimizing noise levels and effectively dampening vibrations.

Hydraulic hammers available in a number of energies

The AB series of hydraulic hammers from Rebel Attachments, a brand by Allied Pedestal Boom Systems, includes 13 models ranging from the AB 307 to the AB 4580. The lineup features models spanning from 550 ft.-pounds to 14,000 ft.-pounds, and the hydraulic hammers fit 3- to 80-ton carriers. Features of the breakers include a silenced, enclosed bracket; a stroke adjuster for variable-speed control; anti-blank fire; and onboard shock damping. Auto-lube systems are available for the hammers, as well. AB series breakers feature two moving parts; an oversized accumulator that protects the hydraulic circuit; and oversized tie rods that are designed to last longer.

Solutions for a variety of equipment

Okada America’s 15 TOP Series hydraulic breakers range in energy classes from 150 ft.-pounds to 15,000 ft.-pounds, providing solutions for skid-steers, compact excavators, track loaders, backhoes and excavators. A large-capacity accumulator reduces pressure spikes to protect the carrier hydraulic system. Nitrogen gas cushions the piston on the upstroke, eliminating the need for shock absorbers and increasing the piston downstroke force. Also, a central grease port allows the breakers to easily adapt to most auto-lube systems. And a long stroke design reduces shock loads and vibration that can cause machine stress and operator fatigue.

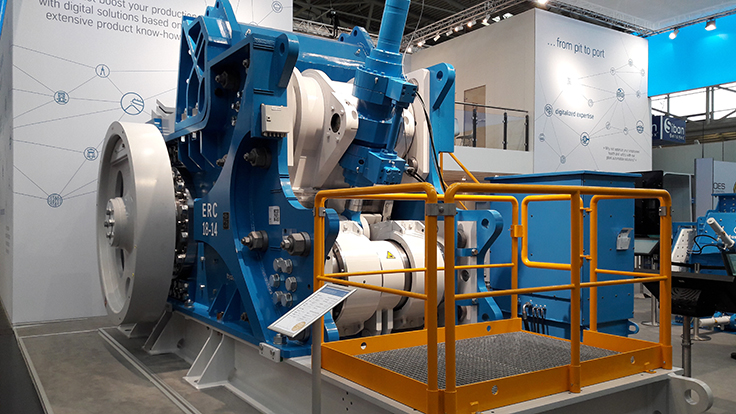

Innovation delivers new approach to primary crushing

The ERC (eccentric roll crusher) is a hard rock crusher featuring a low-wear design and durable components that enhance efficiency, according to thyssenkrupp. Because of its flat, robust design with an integrated screen and high throughputs of up to 8,000 metric tph, thyssenkrupp says the ERC is suitable for operation in primary crushing; stationary, mobile or semi-mobile crushing; with hard rock and ores; and underground or aboveground.

Power-to-weight ratio stands out on breakers

Montabert offers a full line of hydraulic breakers with an unrivaled power-to-weight ratio, according to the company. All breakers contain internal automatic frequency control, automatic pressure regulation, overflow protection and blank fire protection. The breakers provide an adjustment feature with up to 15 different working frequencies, even using minimal flow. The automatic pressure regulators eliminate variation, Montabert says, meaning users don’t need to monitor hydraulic parameters or power settings during operation. Overflow protection is standard, the company adds, as it is automatic and goes unnoticed by operators. The blank fire protection reduces the energy exerted by the strike piston within the cylinder, reducing wear and tear.

Hammers, pedestal booms for range of applications

NPK Construction Equipment offers a line of 16 heavy-duty hydraulic hammer models, with impact energy classes ranging from 150 to 20,000 ft.-pounds. Top brackets are designed to fit any size and brand of excavator, NPK says, and the hammers include anti-blank fire and shock-absorbing features. Additionally, NPK’s line of pedestal boom systems spans 17 models, with a horizontal reach ranging from 13 to 38 ft. The pedestal booms are designed for all types of stationary and portable crusher installations, the company says. Heavy-duty construction enhances reliability and assures long, trouble-free operation, NPK adds.