Continental highlights conveying tech, equipment at ConExpo

As a remote, drone-based system, Conti ConveyorInspect helps protect service technicians by avoiding time-consuming, manual inspections, according to Continental. Photo: Continental

Among the many equipment and technology offerings Continental has at ConExpo-Con/Agg are several pieces designed to improve conveyor efficiency, maximize uptime and more.

Products on display are the Conti ConveyorInspect drone system, the Conti LoadSense monitoring system, Conti SurfaceProtect and the Direct X conveyor belt.

ConveyorInspect

According to Continental, Conti ConveyorInspect allows operators to easily know the condition of their belts and idlers, quickly locate the exact position of failing idlers, and track changes in rotating components over time. With this real-time reporting, operators can better estimate their system’s component life and plan their maintenance, the company says. This helps prevent costly damage of conveyor system components and minimizes downtime.

Once collected, visual data is uploaded to the cloud via the ConveyorInspect portal, and the data is processed and analyzed by an artificial intelligence-based data pipeline. The data analysis and reports can be reviewed with the ConveyorInspect app, which is available on desktop and mobile platforms.

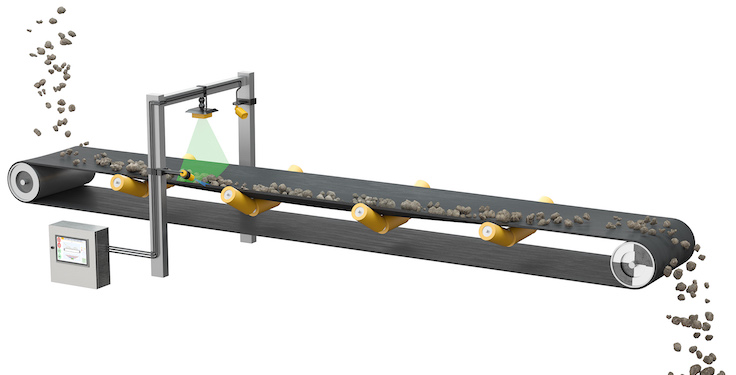

Conti LoadSense monitors the load’s center of gravity on the belt, as well as load distribution along the entire conveyor length, 24/7. Photo: Continental

LoadSense

Continental’s Conti LoadSense monitoring system can be used in almost all industries where conveyor belt systems are used, according to the company.

The system combines radio wave detection and ranging along with ultrasonic sensors to calculate the volume and position on the belt of the material being conveyed. The system scans the material and conveyor belt from different angles to determine the position of the load and the belt. From the data collected, the system can accurately calculate the volume of material being conveyed.

“Having this real-time monitoring allows operators of stone, sand or gravel quarries to measurably increase productivity,” says Patrick Raffler, who is responsible for digital solutions for the conveying industry at Continental. “At one German gravel plant, operators were able to increase output by up to 100,000 tpy after employing the Conti LoadSense radar-based monitoring system. The plants run more economically due to the automatic material detection, and the system reports deviations before losses occur, preventing expensive cleanup costs.”

Compared to traditional monitoring technologies such as lasers or belt scale, Conti LoadSense’s radar sensor requires less maintenance and is less sensitive to external influences like dust rain, and vibrations.

The Conti SurfaceProtect system automatically and continuously scans for damage to belts to reduce the risk of catastrophic belt failure and minimize downtime. Photo: Continental

SurfaceProtect

Continental’s laser-based Conti SurfaceProtect system continuously monitors the surface of flat fabric or steel cord conveyor belts in industrial and mining applications.

The system automatically and continuously scans for damage to the belt to reduce the risk of catastrophic belt failure and minimize downtime. Conti SurfaceProtect evaluates the belt for cuts, gouges or large impact damage events, as well as surface adhesion issues. The data is continually analyzed and reported, alerting operators to the exact position and size of any damage, even for difficult-to-access conveyors.